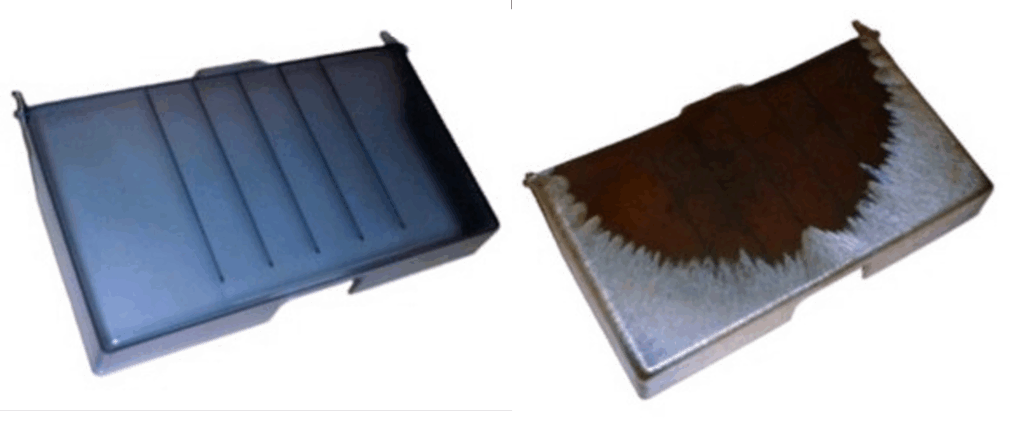

Imagine producing this cover in a transparent material with a nice matt finish and out of the blue a heavily degraded part appears, sometimes complete, sometimes partially filled. You frantically check the machine, settings, material, tool but you find absolutely nothing out of the ordinary.

The machine produces another 5 – 6 parts, the defect diminishes in severity until it looks like it never even happened. All it leaves behind are some very degraded parts and the question “What happened?”

Fig 1. On the left is the part showing heavy degradation caused by bridging. Actual customer parts.

There could be several reasons why suddenly heavily degraded parts show up. Reasons could possibly range from material contamination with an incompatible material, machine malfunction, water leakage etc.

One of the characteristics of the defect discussed in the post is often it’s sudden and unexpected appearance going from a good part to a defect part. The first part usually shows the defect in full force and there is no gradual ramp up in severity as you would expect for instance with a material contamination. The severity of the issue tailors off as shots proceed.

The problem that may have occurred here is an effect called bridging (or arching) that can occur when powders, granulates etc. flow from storage vessels such as the hopper on an injection molding machine. Bridging occurs when a stable arch or bridge forms over the outlet of a storage vessel, preventing the uniform discharge of the granulate. The construction of the arch looks similar to the technique used in building arches or bridges, obviously not as perfectly designed and not meant to survive for centuries.

Fig 2. On the left schematic representation of bridging. On the right ancient arch construction used for a gate.

As soon as the arch is formed the material below it will flow into the machine and consequently the continuous flow of material will be interrupted. As the machine remains in cycle part of the screw will be without material until the moment the arch collapses and material flow is resumed. The presence of a bridge may be so short lived that the flow of material to the intake of the barrel is uninterrupted. In some cases the bridge exist for such an extended period that material flow is interrupted long enough it leaves a space in the barrel without material. The air present there will be closed in by the material that follows, it will be compressed and heated. The combination of oxygen, pressure, heat and an organic material leads to severe degradation of that material .

As said, the bridge or arch can be sustained for a longer period of time, but due to the movements of the injection molding unit in a lot of cases collapses after some time restoring the flow of material. For exactly that reason the cause of the issue may elude you because material flow may have been restored the moment degraded parts start to appear from the mold.

Regarding the root cause of the issue: whether bridging occurs depends on a number of factors. One of the factors involved is the angle of the hopper wall. A too sharp angle facilitates the formation of bridging. The outlet should be sufficiently large with respect to the granule size. The wall should be smooth and clean to facilitate material flow.

Should bridging occur regularly, the placement of a spreader in the hopper may help with material flow. Mechanical devices such as rotating blades or a vibrator may prevent bridging and the formation of lumps. Equipment suppliers are usually more than happy to support you in this matter.

If you have any further questions on this subject, don’t hesitate to contact us.